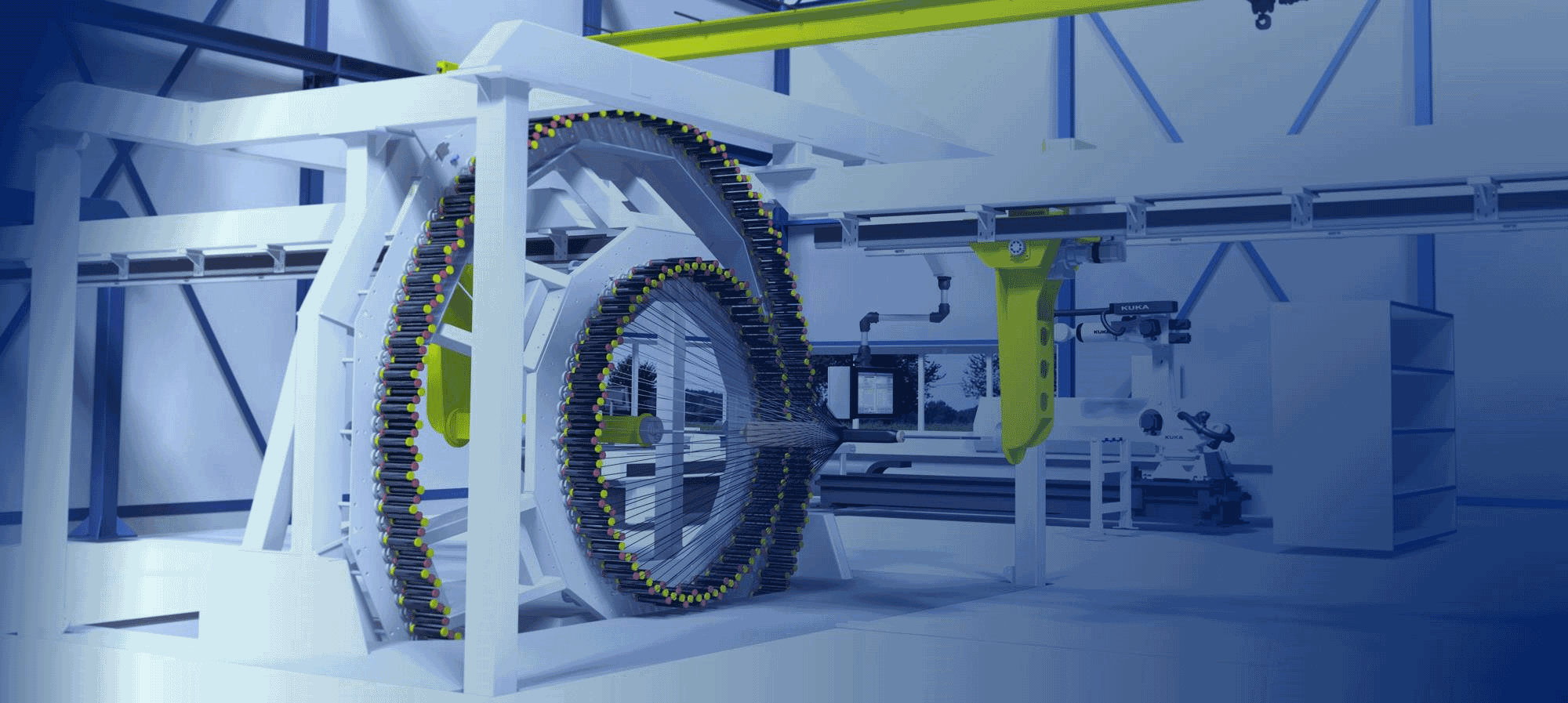

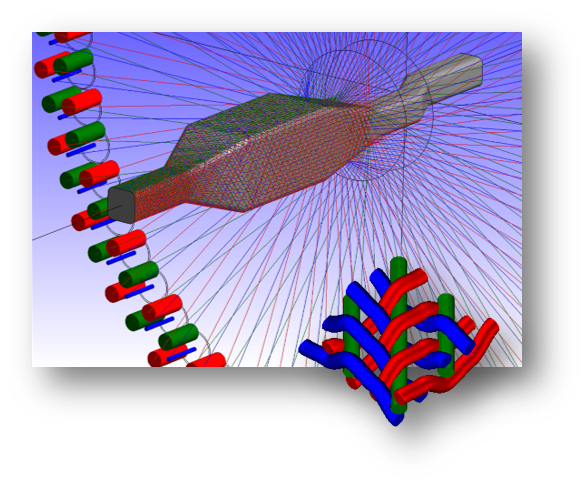

Eurobraider is dedicated in series production of overbraided preforms. The production is made by equipment designed by Eurocarbon B.V. and automated processes. Maybe overbraiding could be a solution for you to outsource preforming activities. See what overbraiding could mean for you in the overbraiding section.

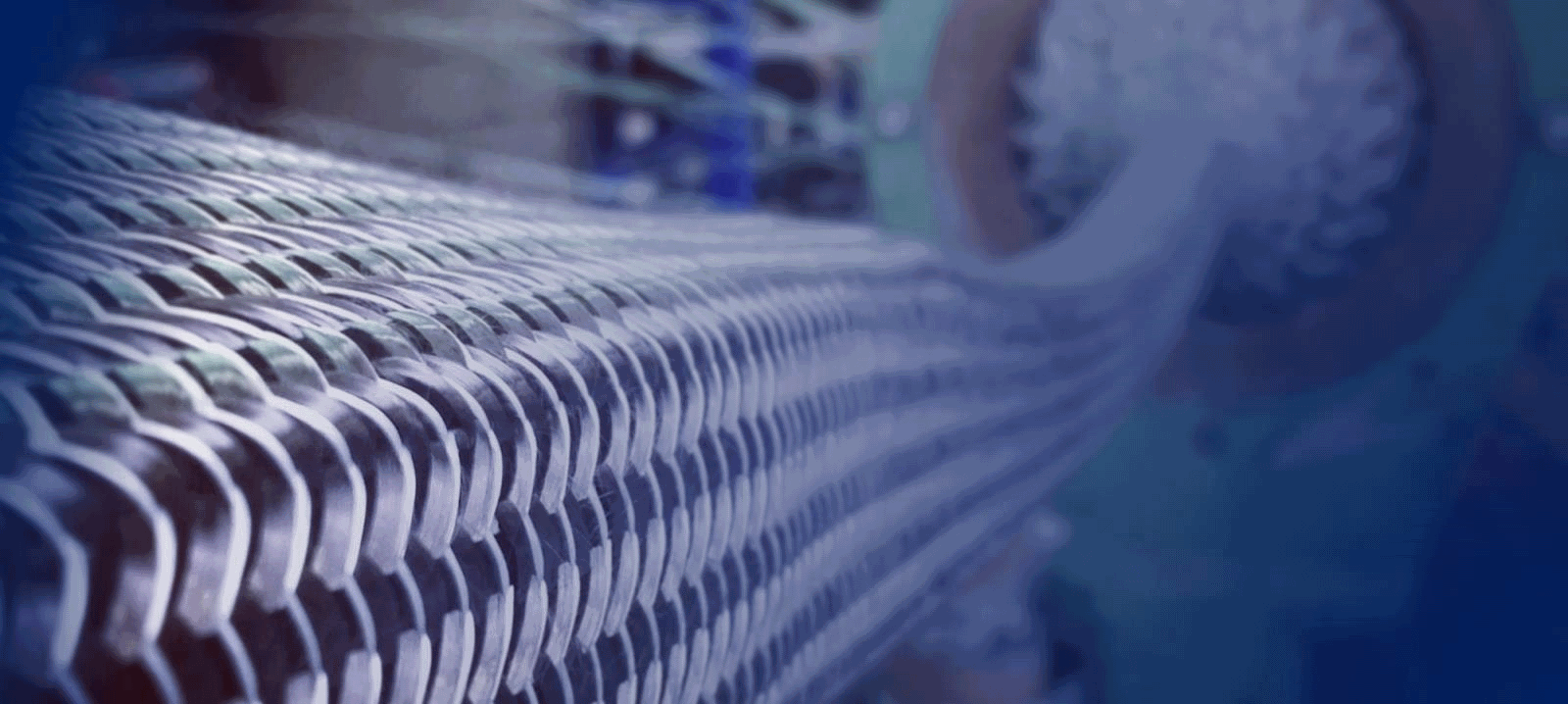

Eurobraider is a sister company of Eurocarbon. Eurocarbon is a producer of braided and woven reinforcements, primarily used for composites industry. These braids and woven tapes are made out of high performance reinforcement fibers such as: glass, aramid, carbon and thermoplastics. In Sittard, we are consulting our customers since 1982, to provide the best possible solution for their application. With our agent network we are close in your country. Check our homepage for your local agent.

Eurocarbon has implemented standard programs to cover a whole range of standard customer‘s applications. All programs are available on stock and ready to ship off the shelf to provide your reinforcements with a minimum of lead time. When tailor made applications are required, check the “minimum requirements” section for braided and woven constructions.

Visitors address

Visitors address